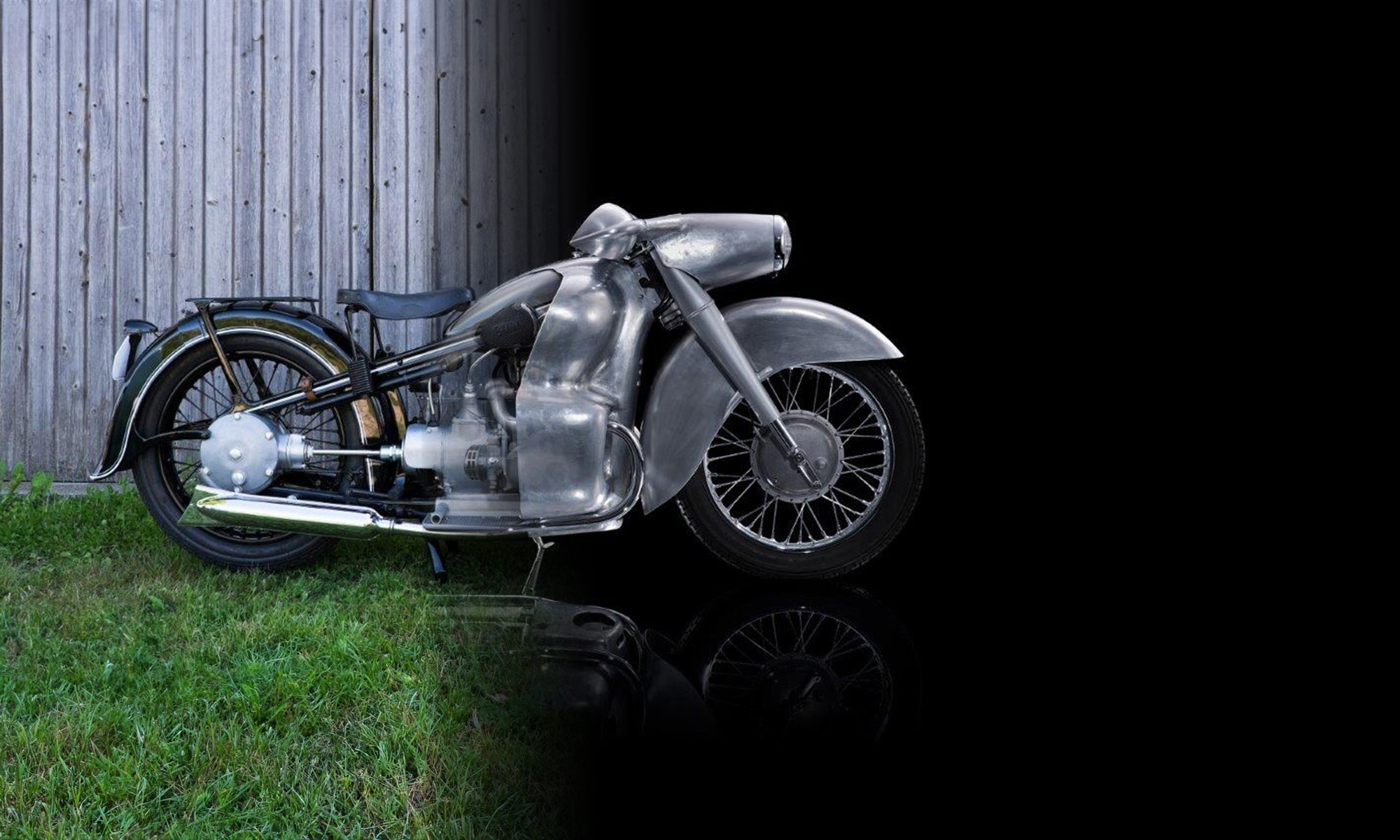

Lepoix BMW R 12 Streamliner

R50 ISDT

BMW R50 ISDT Nr. 550012 produced in Dec. 1954 as a factory machine

1957 exported to USA

The current owner Mike Kowal from the USA asked me to reconstruct the ISDT parts

BMW R69S ISDT reconstruction Sebastian Nachtmann machine

All ISDT parts have been reconstructed according to photographs

Owner Steve Bauer USA

Image copyright: Steve Bauer

Modification BMW R51/3

Reconstruction high exhaust system ISDT with brushed aluminium fenders

Image copyright: A. Beyer

Ready to ride 1928 Sunbeam M9 with original paint work

2015 completion of an original Sunbeam M9

Repair and restoration of the entire mechanics and careful detailed restoration of the existing original substance.

Preservation of all oil-based paint parts as well as nickel parts in matt chemical nickel.

This machine is roadworthied and ready to ride.

Conservation of technical cultural goods

How I understand the preservation of cultural heritage:

Research on authentic restoration

Careful detailed cleaning and corrosion removal

Professional repair of damage

Restoration of the functional mechanical items

Reconstruction and reverse engineering of missing parts

Surface treatment (paint work and galvanic electro plating)

The restoration of chimney wind directional cap for a malt factory.

In 2011, I was commissioned by a large malt factory to restore the old chimney cap.

The hood from the 1920s was completely in sheet steel with a carrier

construction made of angle and flat iron.

Strong surface corrosion with fist-size rust holes was the result of decades of moist and acidic exhaust.

The restoration process

Difficult and careful disassembly of the hood of all components (partial seperation of the individual screw connections)

Glass bead blasting of all usuable steel components.

New fabrication of part components and welding them into place.

Aligning formed sheet metal and frame parts.

New structural angle and flat iron parts fabricated.

Fabrication of a new axle for the rotating cap.

Assembly of the entire chimney cap and matching of all components.

Application of numerous coats of weather resistant zinc chromate paint

Hand sign-writing of the malt factory logo by brush.

Assembly of the complete chimney cap

The aim of the restoration was to preserve as much original substance as possible

so that the age and decades long use remain visible.

The restoration of the chimney cap was carefully and thoroughly restored taking into account the functionality and the stability of this item.

Art-déco style fenders from the BMW R12 and R17

Fabricated in 0,88mm steel sheet with perfect fit, reverse engineered from original sample fenders.

Other sheet-metal components for the models R5 and R51 – R71: Both front and rear fenders in perfect quality and fit. Complete exhaust systems for example R12, R17 and even R66

Road worth motorised bicycle Flottweg

2014 – 2015 Restored motorised bicycle Flottweg with a 98cc 4-stroke motor

for the BMW Group Classic.

The motorised bicycle was completely disassembled and supplied as parts packed in boxes.

Careful and a lot of detailed and difficult restoration of damaged parts (Mudguards, tank, rims, nickel parts). Contemporary paint with nitro lacquer.

Ready to ride BMW R67 ISDT factory machine

Restoration and reconstruction of the original factory machine for the BMW Group Classic, completion July 2013.

Reconstruction of the following missing parts: Exhaust system, oil sump guard, seat cushion, Headlamp stone guard, compressed air bottle, air filter housing.

The peculiarities of this unique factory machine:

Lightweight frame with higher mounted engine, longer fork tubes with special

fork yokes, aluminum tank, all-terrain sport fenders, the first full hub, brakes, all screw fasteners secured with wire and split-pins.

Frame mounted crash bars, oil sump guard, headlamp stone guard, compressed air, bottle, spare bowden cables, six-day clock, leather tool bag and map bag on the tank.

Reconstruction of Royal Sport sidecar with Bugatti-type tail type RSB from the 30’s

Loan of an original unit for the reconstruction of the frame and the sheet metal Bugatti tail boat. Type: Royal sports sidecar RSB 1930’s

Detailed production of the sheet metal body in 1,00mm sheet steel, welded, folded and riveted. Frame construction in 50mm steel tube and welded.